WHY IS APPLYING PROPER TORQUE IMPORTANT?

In industrial applications proper torque is important for safety, reliability and performance. Under and over tightening critical fasteners can lead to product failure causing downtime, higher costs, potential injury and more.

Safety & Performance: Applying accurate torque is critical to assembly applications, engines and precision equipment.

Creating a proper clamp load is the main objective when applying torque to a fastener. Engine cylinder heads, pipe couplings, wheels, all need to be “clamped” uniformly to specific torque values.

There are three main factors that affect the correct application of torque: (1) Condition of components, (2) Accuracy of torque instrument, (3) Properly applied torque values.

Applying torque incorrectly can lead to stripped threads, premature loosening or broken fasteners that can cause catastrophic failure. Leaking joints may cause engine or equipment failures

TIGHTEN EVERY FASTENER TO IT’S EXACT SPECIFICATIONS

Applying accurate torque is critical to assembly applications, engines and precision equipment. Snap-on has the perfect torque option for your specific industry. For more information on the entire line of torque products, contact your Snap-on Industrial Representative.

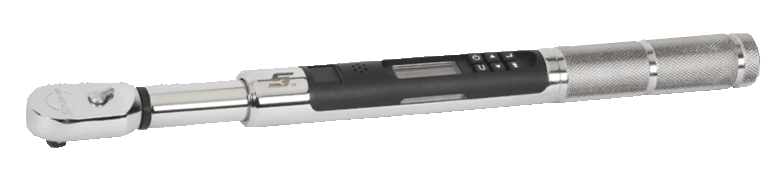

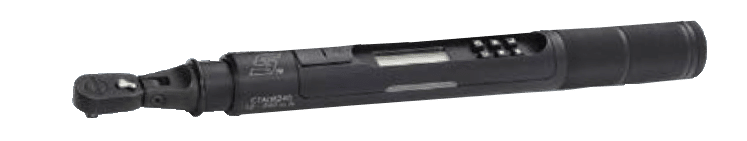

DIGITAL TORQUE

+/- 2 % TO +/- 3 % ACCURACY

Better accuracy with smaller scale increments and programmability means you can torque to exact tolerances.

CONTROLTECH®

Fully programmable and configurable for reliable, consistent and repeatable torque application. Download your torque data with USB.

TORQUE SCREWDRIVERS

+/- 2% Accuracy

MULTIPLIERS

+/- 3% Accuracy

TORQUE WRENCHES

+/- 2% Accuracy

CONTROLTECH-LINK®

The same features as ControlTech® but with added wireless linking to plant level manufacturing execution systems through Snap-on’s new cutting-edge controller. Records and stores all torque data AUTOMATICALLY.

CONTROLTECH® WITH BLUETOOTH®

The same features as ControlTech® but with added Bluetooth®. Export your torque data wirelessly to your device using the ConnecTorq App.

TECHANGLE®

Get better accuracy with smaller scale increments as opposed to “click-type” wrenches.

TORQUE SCREWDRIVERS

+/- 2% Accuracy

TORQUE WRENCHES

+/- 2% Accuracy

MECHANICAL TORQUE

+/- 3% TO +/- 6 % ACCURACY

Provides consistently accurate readings and rugged, trouble-free performance.

QDRIVERS

+/- 6% Accuracy

TQ SERIES (SPLIT-BEAM) +/- 4% Accuracy

QE SERIES

+/- 3% Accuracy

MTM MULTIPLIERS

+/- 4% Accuracy

PTM MULTIPLIERS +/- 5% Accuracy