TORQUE

Versatorq® Torque Metering/Data Acquisition System

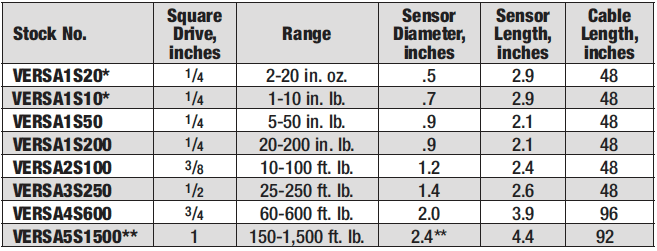

The Versatorq system can be used for any job requiring repetitive torque applications or regular inspection of fastener torque. This system can also be used to verify pneumatic and mechanical torque wrench accuracy. Peak torque can be captured by using a rotary sensor with a

- Versatile – battery operated and lightweight, with available ranges from 2 in. oz. to 20 in. oz. to 150 ft. lb. to 1,500 ft. lb. and 7 units of measure: in. oz., in. lb., ft. lb., Nsm, dsNm, kgm, and kgcm. The Versatorq system can be used with sockets, extensions, universal joints, ratcheting drivers or any of these combined

- Data Aquisition – store and recall up to 3,500 readings. An internal memory backup battery retains setup and last memory data for up to 10 years

- Track or Peak Mode – track mode displays applied torque value and peak mode displays highest torque value

- Easily Calibrated – customer calibration supports ISO9000. Instructions for step by step calibration provided in the users manual

- Smart Sensors – built in EEPROM memory chip stores sensor identification and calibration factors. Factory calibrated, a sensor retains its accuracy with all Versatorq meters; just plug in the desired sensor. Periodic recalibration is necessary

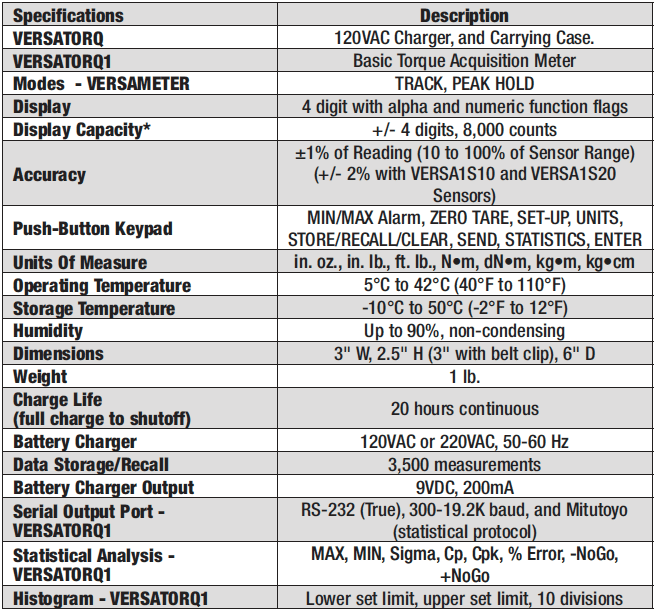

Versameter

Electronic Torque Acquistion Meter

Performs most of the same functions as the Versatorq Torque Acquisition Meter. Will not perform the data storage/recall, statistical analysis and histogram functions and does not offer the serial output port feature

non-impact power tool operating at less than 1,000 RPM and being driven into a soft joint. Inspectors can check critical fastener torque and record data for quality audits. Perfect for process quality control. The Versatorq system can internally perform statistical analysis, including histograms, and print to a serial printer.

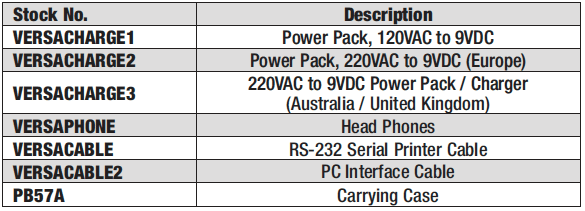

- 120VAC/220VAC, 60 Hz Adaptor – rechargeable battery and belt clip allow you to take it to the task or use it at the bench with the optional table stand and AC adaptor

- PC Statistical Analysis Output – download histogram, minimum and maximum reading, mean, sigma N, sigma, Cp, Cpk, % error and number of readings under and over tolerance

- Serial Port Interface with Computer or Printer – true RS-232 communications port for downloading to computer or serial printer or configurable to MITUTOYO statistical printer protocol

- Visual and Audio Cues – analog bar graph at top of display provides a live indication of applied torque. An OVER warning flag comes on to indicate that maximum sensor range has been exceeded. Green MIN LED indicates lower tolerance has been achieved, and Red MAX LED indicates upper tolerance has been exceeded. Audio alarm produces a distinctive 2 kHz tone. Includes an audio output jack for optional headphones in a noisy environment

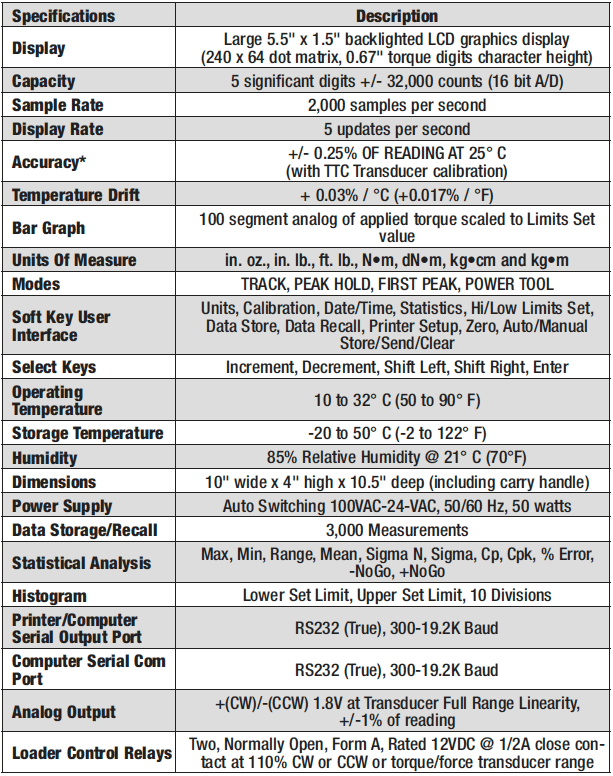

Versatorq1®/Versameter® System Specifications

*Versatorq display ignores torque input less than .5% of full scale in track mode and 2.0% of full scale in peak mode.

NOTE: Please reference the Versatorq instruction manual for the sensor ranges and resolutions in different units of torque measurement.