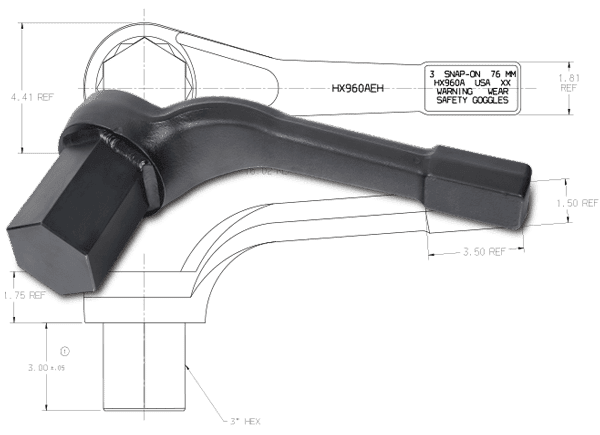

TOOL CUSTOMISATION

CUSTOMISATION YOU CAN COUNT ON

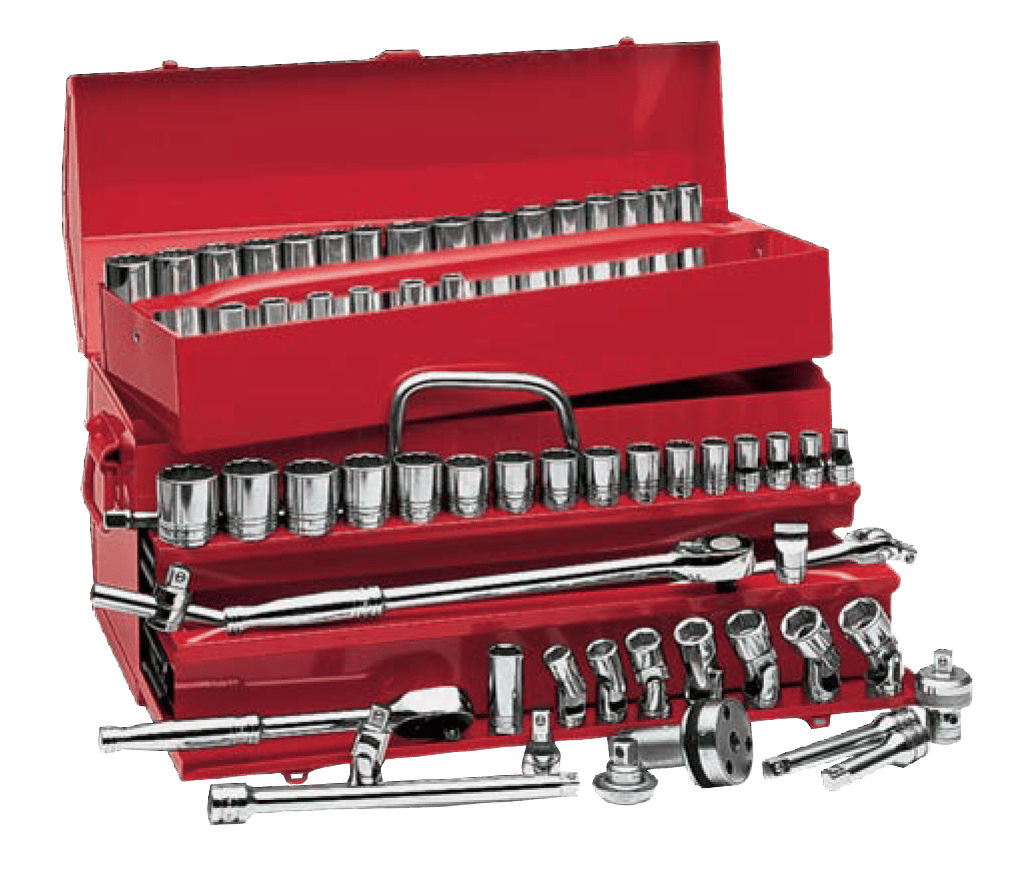

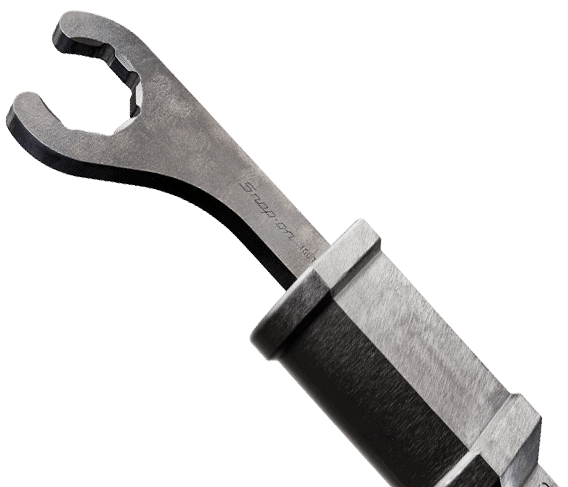

Every job calls for a different set of tools. Snap-on delivers an unprecedented level of customisation to address your unique requirements. From custom kitting solutions, to engineering new custom tools to deal with your specific problem, if you need to find the right tools for your job, you’ve come to the right place.